As is known to all, alumina ceramics have been widely used in electronics, machinery, chemical industry, metallurgy, aerospace and other industries because of their excellent properties, and become one of the world 's largest consumption of special ceramic materials.

However, because of the characteristics of alumina such as more cation charge, smaller radius and stronger ionic bond, the lattice energy of alumina is larger and the diffusion coefficient is lower. The sintering of alumina ceramics is mainly accomplished by recrystallization of crystals, which leads to the high sintering temperature of alumina ceramics. High temperature means high energy consumption and high cost, so reducing the sintering temperature of alumina ceramics is of great significance to the production of enterprises. How can the sintering temperature of alumina ceramics be lowered?

Low Temperature Sintering of Alumina Ceramics

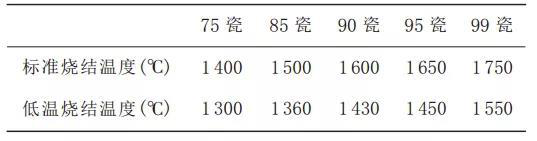

(75 porcelain, i.e. 75% alumina)

Step 1, reduce that particle size of the powder

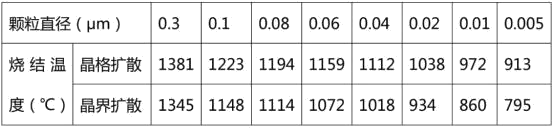

The results show that the finer the particle size, the more defects and the higher the activity of the ceramics, which can promote sintering and the higher the strength of the ceramics. If the particle size of the powder is reduced to 20 nm or less, the sintering temperature of the ceramic can be reduced to 1000 ℃ or less.

Relationship between Sintering Temperature and Particle Size of Powder

(Sintering diffusion activation energy Q=418KJ/mol)

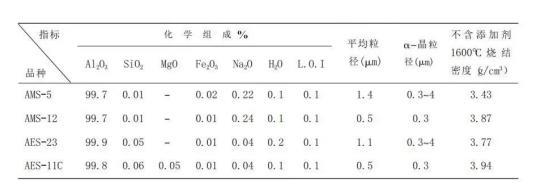

Easily-sintered alumina pow processing index

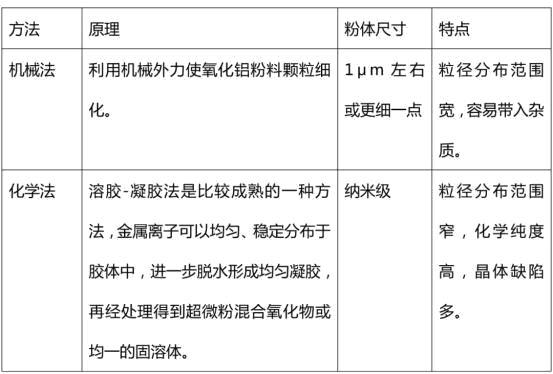

There are two methods to prepare ultrafine alumina powder: mechanical method and chemical method.

Preparation of ultra-fine powder can reduce sintering temperature, but the preparation cost of powder is too high, and the shape of sintered body is difficult to control, not easy to be adopted by enterprises.

2. Adde sintering aid

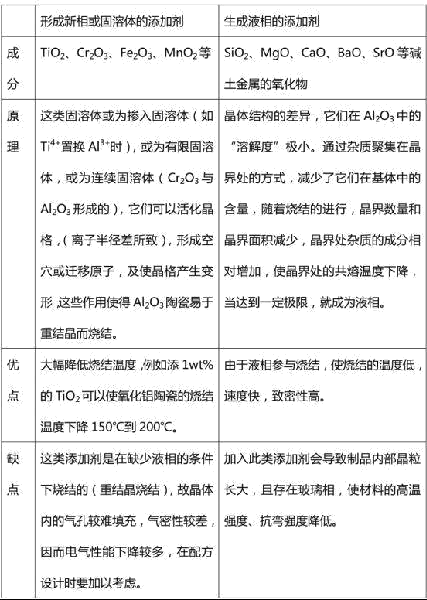

In the production process of alumina ceramics sintering aids are often added to reduce the sintering temperature of alumina ceramics by changing the formula design. According to their different mechanisms of promoting sintering of alumina ceramics, they can be divided into two categories: additives for forming new phase or solid solution and additives for forming liquid phase.

3. Adopt special sintering proces

Special sintering process is to add sintering driving force in the sintering process of alumina ceramics to promote the sintering process of alumina ceramics.

Densification, now the common special sintering processes are mainly hot pressing sintering, hot isostatic pressing sintering, microwave heating sintering, microwave plasma sintering, spark plasma sintering and so on. In addition, vacuum sintering, atmosphere sintering, electric field sintering, ultra-high pressure sintering, activation sintering and activation hot pressing sintering can also reduce the sintering temperature, but because of the high cost, it is generally not considered.

Hot press sintering: unidirectional pressure is applied to the sample at high temperature to promote the ceramic to achieve full densification. For pure alumina ceramics, conventional sintering requires a temperature above 1800 ℃; However, the sintering temperature of 20MPa is only 1500 ℃.

Hot isostatic pressing sintering: Sintering the ceramic body in all directions at the same time, reducing the sintering temperature of the ceramic, sintering at the same time, the ceramic structure is uniform, good performance.

Microwave Heating Sintering: The use of microwave to interact with ceramics because of the dielectric effect on the internal and external properties of the ceramics,

And surface sintering at the same time.

Microwave plasma sintering: Compared with conventional sintering, under the same conditions, the sintering temperature can be reduced by 200 ℃, and the sintering speed is fast, the grain size is small, and the mechanical strength is high.

Spark plasma sintering (SPS): The spontaneous heating of ceramic grains is realized by using the transient high-temperature field generated by pulse energy and pulse pressure, so that the grains are activated. As the sintering method has the advantages of rapid heating, rapid cooling and short holding time, the growth of the grains is restrained, the preparation period of the ceramics is shortened, and the energy is saved.

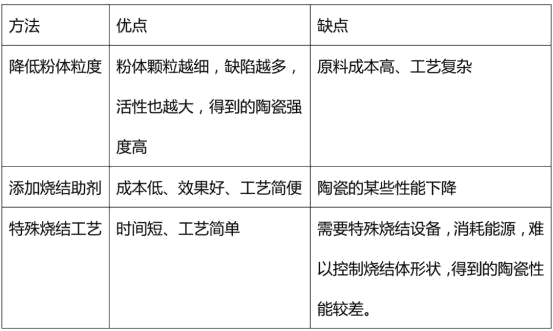

Comparison of Three Methods for Reducing Sintering Temperature

The above method for reduce that sintering temperature of the alumina ceramic are not isolate, and are performed under different conditions

The leading role is different. It can be used in combination with each other in the specific production in order to obtain the best performance

Ceramic products.