Alumina ceramics have excellent properties such as high mechanical strength, abrasion resistance, corrosion resistance, high temperature resistance, high thermal conductivity and electrical

resistivity, and are widely used in high-tech and cutting-edge industries, such as microelectronics, nuclear reactors, magnetic fluid power generation, aerospace, artificial bone and bone joints.

For alumina ceramics with high dimensional accuracy and complex shape, compared with traditional molding process, injection molding has special technical advantages. Ceramic injection molding as a near-

Net forming technology, precise and controllable product size, high mechanical degree, easy to achieve large-scale production, without or only a small amount of machining, which greatly reduces the production cost of ceramics.

Advantages of Alumina Injection Molding

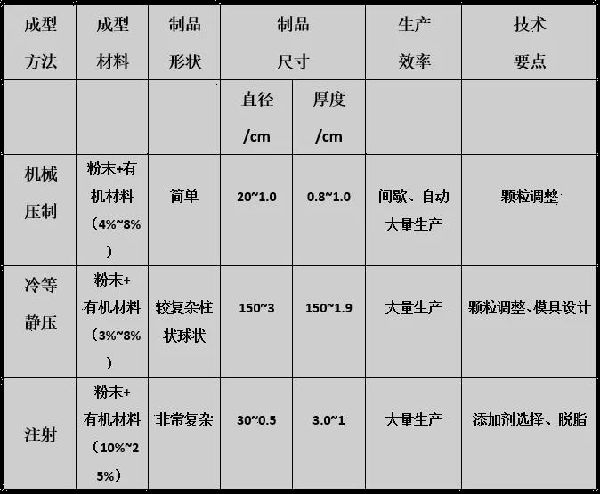

The ceramic injection molding technology has the following advantages compared with the traditional molding method:

(1) high degree of mechanization and automation in molding process; (2) The ceramic parts with various complex shapes can be formed near the net shape, so that the sintered ceramic products do not need machining or less machining, thus reducing the expensive ceramic processing cost; (3) The molded ceramic products have high dimensional accuracy and surface finish.

Comparison of Injection Molding and Other Molding Methods

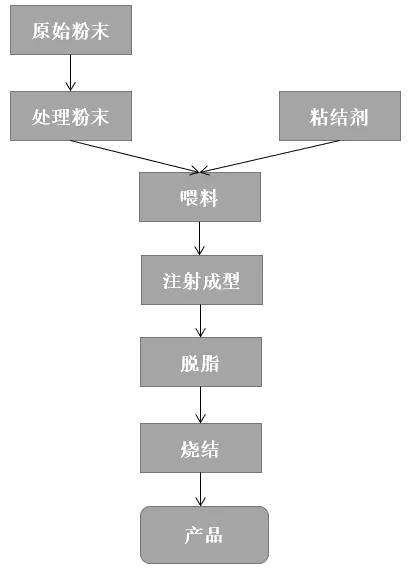

Process flow of alumina ceramic injection

The process of ceramic injection molding mainly includes four steps: feeding, injection molding, degreasing and sintering.

Process Flow Diagram of Alumina Ceramic Injection Molding

(1) Selection and Optimization of Powder

It was found that different Al 2O 3 powder mixing ratio resulted in different injection molding binder ratio, feed fluidity, product shrinkage and grain boundary diffusion. The alumina is a composite material prepare by doping other ceramic or metal materials on that basis of alumina, wherein Cr 3C 2, SiC, Ti, WC, ZrO 2, Al and MgO are doped in the alumina

The composite ceramic material can enhance dislocation and inhibit grain growth, which is beneficial to grain refinement and improve the mechanical properties of the product.

Another research area of powder preparation is the effect of powder average particle size, bulk density, powder shape, specific surface area, particle gap on feed fluidity and product quality. Powder as the main material of injection molding, the most important requirements are small particle size and regular shape. The powder with small particle size has good fluidity, large filling amount and low sintering shrinkage during injection molding.

(2) Binder

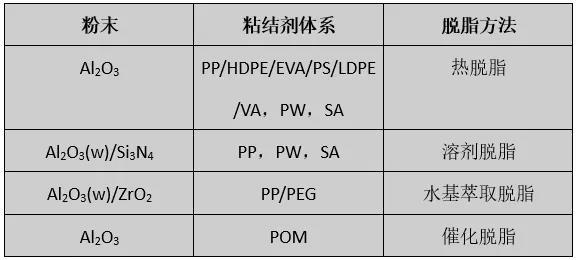

Selection of binder

The selection of binder system is the core of alumina ceramic injection molding. It not only directly affects the injection properties of the feed, but also determines the degreasing method and affects the final properties of the product. The binder system has two basic functions in the process of injection molding. The second is to ensure the strength of the blank.

At present, the most commonly used binder in alumina ceramic injection molding is composed of paraffin wax (PW), polypropylene (PP) and stearic acid (SA).

Binder and degreasing method for ceramic powder injection molding

Effect of surfactants

According to the rheological theory, surfactants largely control the properties of the ceramic feed, and the stability of the feed will increase with the thickening of the absorbent layer on the surface of the ceramic particles. In the process of injection molding of alumina ceramics, the amount of surfactant varies with the other components of the binder, and the amount of surfactant varies from 1% to 5%.

(3) Degrease

Defatting process is the longest time-consuming process in injection molding process, and also the most critical process in quality control. Improper defatting will cause many defects in products. A large number of studies have shown that degreasing process and the addition of binder are inseparable, different binder, the use of degreasing methods are also different.

(4) Sintering

The defatted ceramic green body is a porous shaped body with low density, which needs to be densified and sintered at high temperature to obtain dense ceramic parts with required dimensional accuracy and fiber structure.